Product Overview

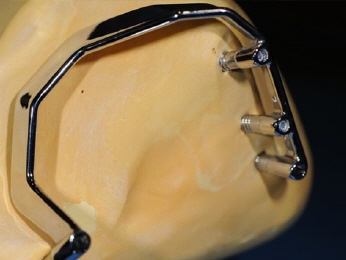

We create bars on implant fixtures of almost any design from any manufacturer using homogenous material. The bars can be in any profile like Dolder® U-shape, Dolder® egg-shape, Preci Horix, round or according to a special design. In order to mount locators and attachments, we have the capacity to mill high precision threads. Upon request, we can also supply you with the original bar Locators® of Zest Anchors.

Because of our highly precise methods of working, the bars fit virtually stressfree on the implants within the tolerance of 0.01mm. We are happy to assist you in finding the right 3D-construction for your cases, where the implants are placed in extraordinary positions.

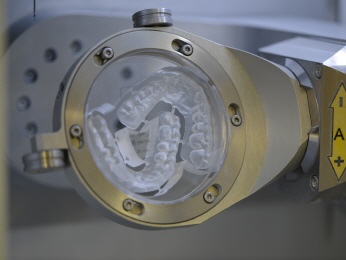

After the virtual design of the bar, the dental lab receives a 3D-image of the predesign. This enables the dental technician to make adjustmenst to the design, which will modify the production process. As soon as the dental lab agrees with the design, the image file is signed and sent back to us with the OK for production.

We produce bars in the following materials:

Titanium Grade 5

Chrome Cobalt

Zirconium dioxide (limited indications)

Thanks to our industrial milling centers, like Agie Charmille and DMG Mori Seiki, the orders are manufactured with the highest precision.

If you wish to receive a bar in a different material, we kindly ask you to contact us in order to make the necessary arrangements.

Our operations protocols are streamlined for precise yet rapid production. Most of the time we can deliver your order within 24 hours after it is placed.

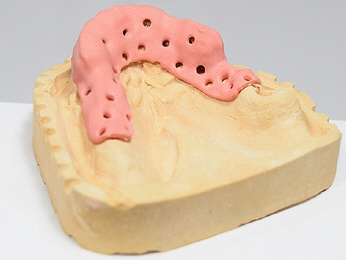

This restoration includes a screw-retained bar and a secondary structure in TRINIA™. Thanks to riders the framework can be put over the screw-retained bar. TRINIA™ is a metal-free material with multi-directional interlacing of fiberglass and resin in several layers.

Advantages: Metal-free - durable - elastic - biocompatible - lightweight

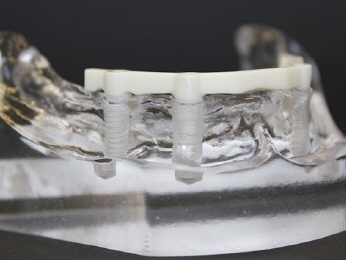

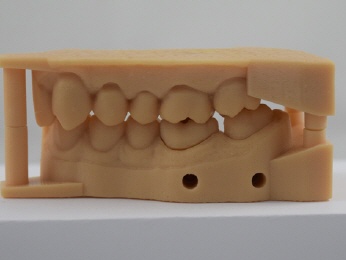

Frameworks for implant supported bridges are designed virtually, according the 3D scandata based on the model or the draft of the restoration. We create frameworks for denture type bridges and for conventional procelain application.This gives us the possibility to fully respect the customers needs and requests. Before the production, the customer receives an image with the virtual predesign of the bridge. This gives the dental lab the chance to make some adjustments and to check the product on the screen before production. We also provide so called copy mills, which are based on the model of the restoration. In this process, there is no predesign necessary and the bridge will be produced from fully homogenous material, according to the 3D-scandata received from the model.

We produce bridges on the most common implant fixtures. If you wish to have a bridge on an implant style that has not been added to our library previously we can immediately acquire the devices necessary to proceed.

All our bridges are produced with the precision of 0.01mm, in order to provide a totally stressfree attachment in the patient. We are happy to assist you in finding the right 3D-construction for your cases, where the implants are placed in extraordinary positions.

We produce frameworks in the following materials:

Titanium Grade 5

Chrome Cobalt

Zirconium dioxide (on titanium bases)

PMMA (on titanium bases)

If you wish to receive a bridge in a different material, we kindly ask you to contact us in order to make the necessary arrangements.

Our operation protocols are streamlined for precise yet rapid production. Most of the time we can deliver your order within 24 hours after it is placed. Zirconium dioxide after 48 hours because of the sintering.)

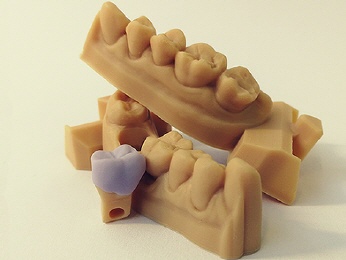

Customized abutments can either be designed virtually or produced according to a model. Thanks to our continuousely updated implant library, we are able to produce customized abutments on all most known implant levels. As by Thommen Medical authorized milling center we produce titanium abutments on Thommen interfaces with original parts. In Switzerland, we are the only provider of individual titanium abutments on Camlog fixutres, delivered with original parts.

Customized abutments in titanium grade 5 and chrome cobalt are manufactured in one piece with an implant fit within 0.01mm. Our specially designed scanflags enable us to determine the exact implant position and rotation.

Where the customized abutment is being designed virtually, the dental lab has the possibility to check the work with a viewer, before it goes into production.

If you already have a scanner and a design software, which exports *.STL-files, we produce your customized abutment according to your data and design.

We produce customized abutments in the following materials:

Titanium Grade 5

Chrome Cobalt

Zirconium dioxide (on titanium base)

Synthetics (on titanium base)

IPS e.max® (on titanium base)

To guarantee the stability of abutments in zirconia, synthetics or IPS e.max®, we produce them in two parts (with titanium bases). The interfaces for the most common titanium bases can be found in our library.

Thanks to streamlined workflows, we are able to deliver your order after only 24 hours. Zirconium dioxide after 48 hours because of the sintering.)

Cemented solutions to natural teeth can be produced according to a resin model or according to the *.STL-file, supplied by the dental lab. There is also a possibility to design the structure virtually, based on a tooth setup.

Bridges and crowns are produced in the following materials:

Zirconium dioxide (white or in basic color, also multilayer)

Titanium Grade 5

Chrome Cobalt

Synthetics

IPS e.max® (max. 3 elements)

Orders produced in metal, synthetics or IPS e.max® can be shipped from 24 hours and orders produced in Zirconium dioxide from 48 hours after receipt of written order.

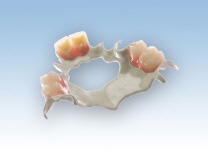

We are proud to be the first certified Swiss milling center of Solvay Dental 360™. We now design and mill metal-free partial prosthetics in Ultaire™ AKP.

Ultaire™ AKP is the high-performance polymer for dental applications of Solvay, the world leading manufacturer of high-perfomance polymers.

The new material offers the following advantages:

- Frameworks in Ultaire™ AKP are extremely lightweight, without aftertaste, non-corrosive, non-toxic, non-irritating and

eliminate the risk of hypersensivity reaction to metal

- Patients appreciate the tooth-colored aesthetics and the low thermal conductivity

- Due to the special E-module of Ultaire™ AKP (similar to the bone) the patient has no feeling of tension

- The lab appreciates the efficient workflow and the high precision fit of an Ultaire™ AKP restoration

Detailed information. [1’590 KB]

NEW: Ultaire™ AKP is now available in two colors, white & beige.

NEW: Secondary telescopic restorations made of high-performance polymer Ultaire™ AKP from SOLVAY, the world leading manufacturer of high-performance polymers.

NEW: Ultaire™ AKP is now available in two colors, white & beige.

We offer the following options:

- Single secondary telescopic crowns to be glued into the prothesis base

- Secondary telescopic crowns combined with metal-free partial prosthetics or internal framework

Please do not hesitate to contact the competent allshape staff if any questions arise.

We are looking forward to your call!

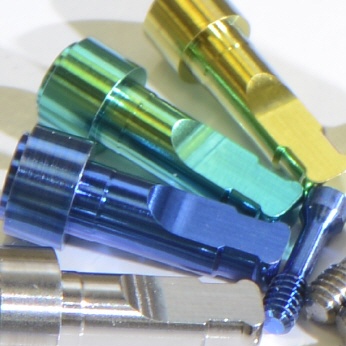

As a service to our valued customers we offer now a variety of auxillary marerial. With this service, you receive all your components from one partner.

The portfolio of auxillary material includes:

Screws in titanium, original screws of Thommen Medical, replicas for the most common implant interfaces, original titanium bases of Thommen Medical, gold riders of Cendres + Métaux SA, Locator® of Zest Anchors

We are constantly adding new products to our portfolio. For further information, please call us, we are happy to assist you.

Our offer is constantly being expanded. Contact us, we will be pleased to advise you.

We also design and produce small series of specially manufactured devices for the medical field and for other highly technical industries.

There is no limitation in regard to the variety of products or materials to be machined. Thanks to our highly precise 5-axis simultanious milling centers, state-of-the-art infrastructure and latest software, we are able to meet all our customers' requirements and to produce high quality products.

The series size varies from single piece production up to small series in lots of 500 pcs./lot.